Estimating the CO2 intensities of EU refinery products: Statistical Regression Methodology

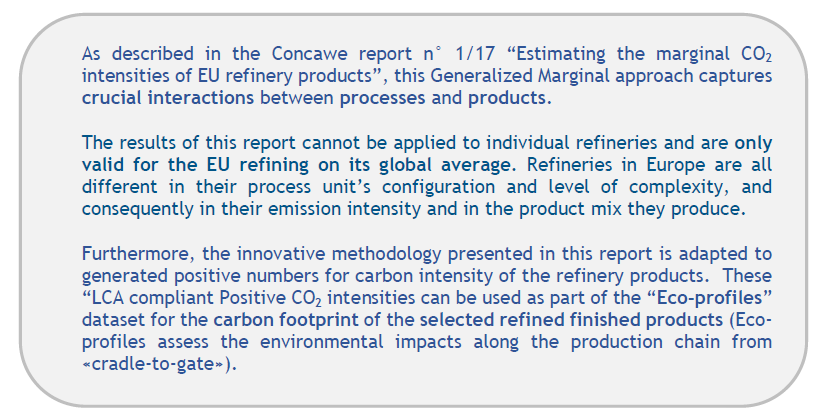

Report no. 15/22: This study aims at estimating the CO2 intensity of petroleum products at the gate of an average EU refinery (refining step of the production process, excluding upstream and downstream emissions) using a novel approach, which reconciles economic relevance with accounting conventions in joint production industries. It revisits and finds a fair and logical way to distribute total CO2 emissions from the EU refineries over the most significant finished products, selected from the refinery slate.

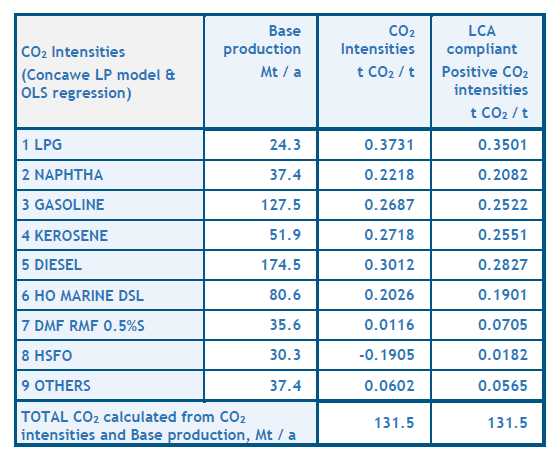

The refinery linear programming model of Concawe is used to generate randomly 500 consistent production level data around the calibrated reference year 2019. Firstly, an innovative restricted regression methodology is applied to determine the linear coefficients which are equal to the CO2 intensities of the EU finished refined products (see column “CO2 intensities” in the table below). Then, this novel data-driven framework, based on supervised machine learning technics, enables, firstly, to assess causal-based, as it captures the interactions between the process units and the products (necessary for co-production process), and is extended via the restricted regression to provide positive dataset. Secondly the figures are statistically valid (highly robust results) in the area of analysis (+- 5% of the demand).

Lastly, similar to results derived from applying an LCA methodology (both attributional and consequential), this method gives positive CO2 intensities for all products. Therefore, the last column in the table below is labled as “LCA compliant, Positive CO2 intensities”. The final set of CO2 intensities is summarized in the table below:  Various statistical hypotheses are verified to ensure the credibility and robustness of the results. It can be noted that the high sulphur fuel oil (HSFO) shows negative CO2 intensity (2nd column). In a refinery, if the production of high sulphur fuel oil has to be reduced, it would be converted into lighter products, through CO2 intensive process units.

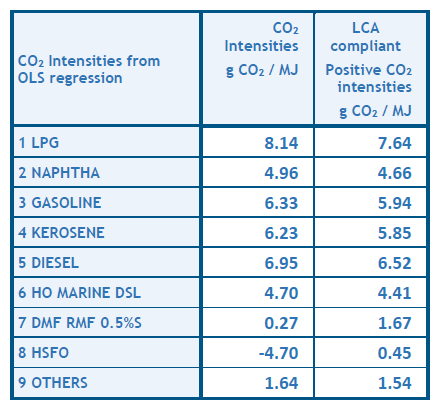

Various statistical hypotheses are verified to ensure the credibility and robustness of the results. It can be noted that the high sulphur fuel oil (HSFO) shows negative CO2 intensity (2nd column). In a refinery, if the production of high sulphur fuel oil has to be reduced, it would be converted into lighter products, through CO2 intensive process units.  In LCA world, it is common to report the CO2 intensities in grams of CO2 per megajoule of product. The table below shows the same CO2 intensities as above, but in g CO2/MJ.

In LCA world, it is common to report the CO2 intensities in grams of CO2 per megajoule of product. The table below shows the same CO2 intensities as above, but in g CO2/MJ.  The estimated CO2 intensities, as well as their confidence intervals, confirm that diesel is more CO2 intensive than kerosene and gasoline. These marginal CO2 intensities are causal-based and, therefore, relevant for policy making such defining the fossil fuel comparators for GHG saving computations. Oil refining is a complex interactive production system for which allocation-based average data are both meaningless and misleading. In this report, we reconciliate, for the first time, the causal relevance with the accounting conventions such as additivity and nonnegativity. The computation principles are transparent and readily replicable by all stakeholders.

The estimated CO2 intensities, as well as their confidence intervals, confirm that diesel is more CO2 intensive than kerosene and gasoline. These marginal CO2 intensities are causal-based and, therefore, relevant for policy making such defining the fossil fuel comparators for GHG saving computations. Oil refining is a complex interactive production system for which allocation-based average data are both meaningless and misleading. In this report, we reconciliate, for the first time, the causal relevance with the accounting conventions such as additivity and nonnegativity. The computation principles are transparent and readily replicable by all stakeholders.